The State of Rhode Island - Alternate COVID-19 Hospitals

Case Study

The State of Rhode Island: Alternate COVID-19 Hospitals

On March 30, 2020, CME Corp received a call from David Schnell, Branch Preparedness Chief at the Rhode Island Emergency Management Agency. He asked if we would be interested in working with him on three different alternate hospitals treating COVID-19 patients in and around the Providence, RI area.

Even though CME was working hard on many other critical COVID-19 projects across the country, we could not refuse the chance to help our home state with their COVID-19 preparedness plan.

Project Time-Line

- March 30- April 1: CME assessed sites with National Guard and project management team

- April 1- April 2: CME government team reviewed equipment lists with operations and clinic staff from two local hospitals responsible for operating the three new facilities

- April 2- April 3: CME sourced all items and began procurement

- April 6- April 14: Products were received at CME’s Warwick warehouse, and were then staged, assembled, and prepared for delivery

- April 15- April 18: Products were delivered to three sites with 50+ trucks and over 20 CME installers and technical services teammates

The Solutions

- Products Needed

- CME maintains an up-to-date quick ship list that was utilized to find much of the equipment needed. Certain items had to be sourced from multiple vendors to get the large numbers needed

- CME created a team focused specifically on this project, including our government sales team and several other key teammates who called to get confirmation of product availability and ship dates from over 50 manufacturers

- Logistics

- CME made the warehouse space available and provided necessary staff to receive, inspect, stage, assemble, and prepare for delivery

- CME opened its warehouse on a Saturday for the National Guard Commander and the Branch Preparedness Chief of the Rhode Island Emergency Management Agency to inspect portions of the received product

- Over 20 CME teammates loaded trucks and delivered product over two and a half days, including a weekend

- Communication and Collaboration

- The project was primarily managed by an equipment planning group with direction from the Rhode Island Emergency Management Agency and the Rhode Island National Guard. All parties involved had to be patient, flexible, and timely in their response

The CME Solution

Who

Project

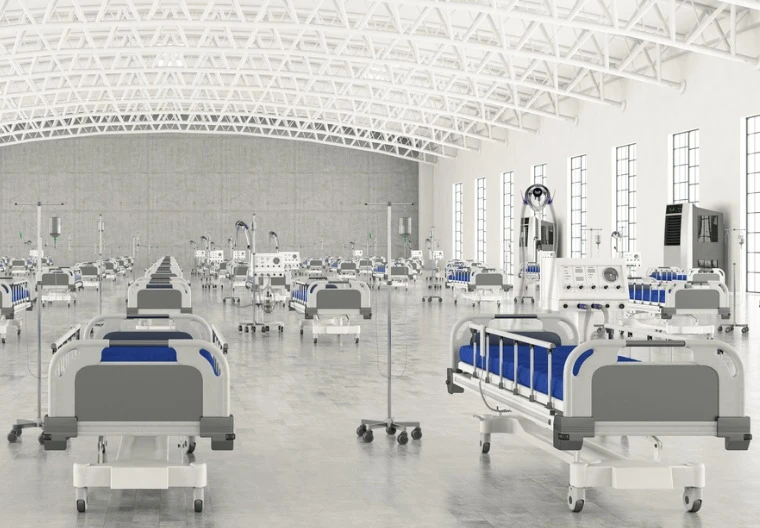

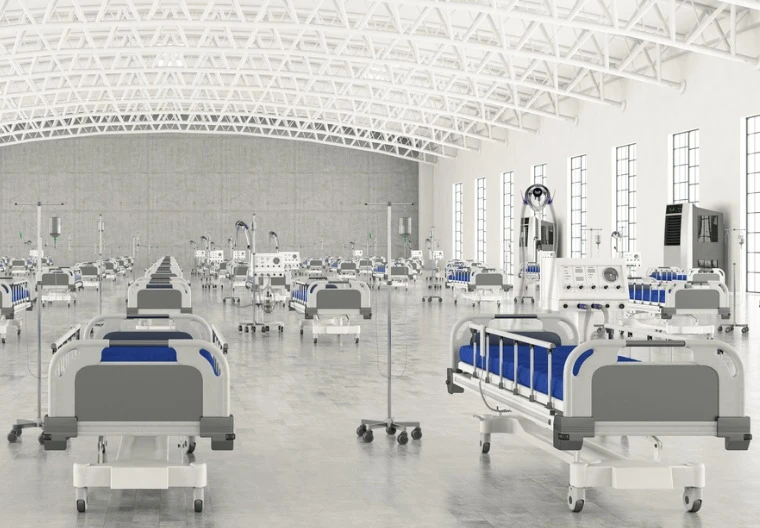

- Plan, source, receive, stage, warehouse, assemble and deliver 15,893 items from 55 manufacturers to three sites in Providence, Cranston, and North Kingston, RI

- Adding 1,385 beds designated for low-acuity COVID-19 patients managed by two large IDNs

- Collaboration between over five government agencies, two hospital systems, a project management team, an equipment planning group, a construction company, Rhode Island Disaster Medical Assistance Team (RIDMAT), and CME enabled the planning and execution of the project.

Government agencies included the National Guard, Office of the Governor, the Rhode Island Department of Health, the Rhode Island Emergency Management Agency, the Department of Defense, and local municipalities.

Goals

- Properly equip multiple alternate hospital sites in a compressed timeframe

- Open all facilities on time

Challenges

-

Products Needed

- The most critical equipment needed for COVID-19 temporary facilities were in short supply or had long lead times. CME was tasked to find equipment that could be delivered within a two-week timeframe

For example, the state needed 1,500 beds/mattresses, 1,200 commodes, and 2,000 privacy curtains (3.6 MILES of curtain) - Equipment lists had to be created in a short timeframe Logistics

- The most critical equipment needed for COVID-19 temporary facilities were in short supply or had long lead times. CME was tasked to find equipment that could be delivered within a two-week timeframe

-

Logistics

- The state of Rhode Island could not provide any storage space for new equipment and had insufficient human resources to provide the staging, assembly, installation, and delivery directly to the rooms

- As equipment was shipped to CME warehouse, some of the government agencies required access to the equipment on the weekend

- Two of the three facilities required the assembled equipment to be delivered in a three-day period including the weekend

-

Communication and Collaboration

- Having many Federal, State, and Local agencies trying to accomplish the same goals with different operating and management systems provided additional complications

Results

- Over 90% of the items were delivered within the timeframe presented

Keys To Success

- Flexibility, accountability, patience and a keen sense of urgency by all parties involved

“Immediately upon being assigned the task of being on the Medical Surge Team, I thought about a local company in Warwick, CME Corp. Upon speaking to the CME staff, I knew I made the right call. They were responsive, understanding the urgency of the situation, and ready and willing to assist!” said David Schnell, Branch Preparedness Chief at the Rhode Island Emergency Management Agency.